Commercial Deployment of Thorium-Based Liquid Fuel Generation IV Nuclear Reactors, Closer

10 November 2020 – Terrestrial Energy USA and Argonne National Laboratory (ANL) have started detailed testing of the Generation IV Integral Molten Salt Reactor (IMSR®). The thorium salt-fueled reactor testing program is part of a broader continuous testing program for the fuels, components and systems used in the IMSR nuclear power plant. The test results will support the licensing process as the first commercial deployment of the IMSR nuclear power plant. ANL will use a variety of characterization techniques and sophisticated laboratory equipment to determine the thermo-physical properties of IMSR against regulatory standards. ANL will prepare and test a fuel mixture in the form of a thorium-based molten salt which replicates the fuel composition during the IMSR operating cycle. Laboratory investigations will include determination of melting point, density, viscosity, heat capacity, and measurements of thermal diffusivity. Terrestrial Energy USA began working with ANL in 2016 after receiving research funding from the US Department of Energy’s Gateway for Accelerated Innovation in Nuclear (GAIN) program. GAIN provides support to the nuclear community which commercializes innovative nuclear technology.

Indonesia, NRE and Coal

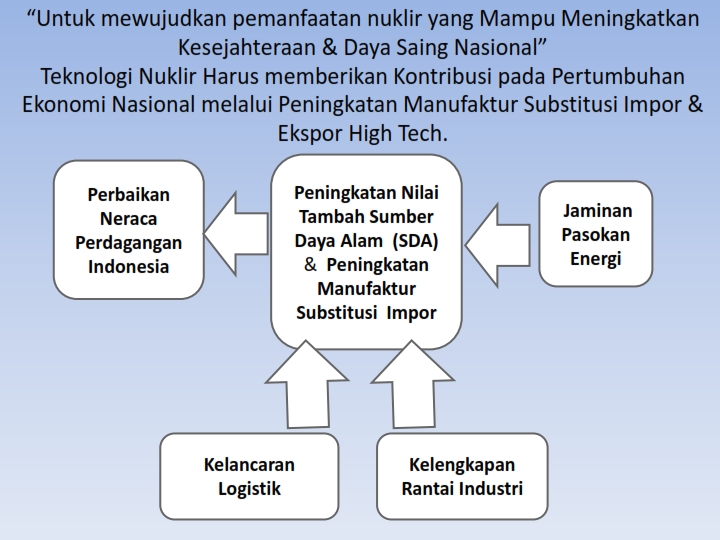

The 2019-2024 RPJM (National Medium Term Development Plan) states that strengthening economic resilience is aimed at growth while still adhering to the commitment of the Indonesian government in the UNFCCC COP 21 of 2015 to reduce greenhouse gas emissions by at least 29% by 2030. For this purpose, it is necessary to strengthen the capacity in managing economic resources and using them to produce goods and services with high added value to meet domestic and export markets. In this context, efforts must be made to increase the GDP contribution of the non-oil and gas processing industry, especially by increasing the contribution of exports of high-tech industrial products. Fulfilling energy needs in this context must prioritize increasing the use of New and Renewable Energy (NRE). If Indonesia relies on its energy supply in a business as usual manner (using EBT 19% of the total energy supply in 2027), then the total CO2-equivalent emissions in 2027 (based on calculations) will reach 234 million tonnes CO2-equivalent. As an illustration, in 2017 the use of EBT was only 8% of the total energy supply in Indonesia. On the basis of calculations, if using EBT 31% of the total energy supply for Indonesia (around 350 TWh) by 2027, the emissions will be reduced by 16% from 234 million tonnes CO2-equivalent. If we use EBT 43% of the total energy supply, emissions are reduced by 36%. The problem is the question related to the ability of NRE energy supply, whether it is able to provide a supply of 31% or even 43% of the total energy supply needs for Indonesia in 2027. Emission reduction requires NRE with a large capacity, as energy suppliers from fossil fuels such as coal. The energy supplier, which has been shown to be able to compete with the energy supply capacity of fossil fuels, is nuclear. The cost of generating electricity from nuclear power plants is more expensive than the costs of generating electricity from coal power plants? Currently in Indonesia, it is illustrated that electricity from nuclear power plants is expensive. Meanwhile, electricity from coal-fired power plants is cheap. This image needs to be examined more carefully, whether the current calculation of electricity prices takes into account the cost of externalities and even the cost of carbon. The cost of externality includes the cost of damage due to PM10, SOx and NOx pollution, while the cost of carbon (i.e. in the form of CO2) is the cost of reducing carbon emissions, for example by means of carbon capture / sequestration or in the form of carbon taxes taken by the government to finance efforts to reduce carbon emissions. BATAN researchers have reviewed the cost of pollution damage on the basis of 2003 references. As a result, the cost of damage due to pollution from PM10, SOx and NOx emitted by PLTU Suralaya, Banten = 23.40 mills $ / kWh. BATAN researchers have also calculated the assumption that the cost of CO2 capture / sequestration is 30 $ / MT CO2 (conversion factor of cost per MT carbon to cost per MT CO2 = 3.7), the result is that the calculation of the cost of carbon in Indonesia = 25.47 mills $ / kWh. On the basis of these calculations, it means that the cost of generating coal PLTU coal, in this case represented by the Suralaya Banten coal-fired power plant, must be added to the cost of damage due to PM10, SOx & NOx emitted by the Suralaya PLTU coal power plant and carbon costs of 48.9 mills $ / kWh. Conclusions from the study by BATAN researchers: 1. The cost of generating electricity from coal-fired power plants without external costs and carbon costs is between 43 to 61 mills USD / kWh, meanwhile the calculation of the cost of generating electricity for High Temperature Gas Cooled Reactor (HTGR) nuclear power plants in Indonesia is between 41 mills USD / kWh to 47 mills USD / kWh. 2. If the cost of externalities is taken into account in the cost of generating electricity from the Suralaya coal-fired power plant, the cost of generating electricity from the Suralaya PLTU will be between 89 mills USD / kWh to 107 mills USD / kWh, and will be even more expensive if the carbon costs are taken into account, which is between 114 mills USD / kWh to 133. mills USD / kWh. While the cost of generating HTR electricity remains unchanged, it remains between 41 mills USD / kWh to 47 mills USD / kWh, as there are no external costs and no carbon costs. NOTE: The latest data on China’s HTR investment price is € 667 million and the electricity price for optimal investment is 79 € / MWh = 9.32 cents USD / kwh (1 € = 1.18 USD).

“There is no reason not to use local technology in processing rare earth elements bearing ore”

Rare earth elements are 17 lanthanide elements grouped in Light Rare Earth Elements (LREE) and Heavy High Rare Earth Elements (HREE). Among them, Neodymium-Praseodymium (Nd-Pr) which is very important for the manufacture of permanent magnets that are small but powerful so that they are widely used in civilian and military electronic devices (loud speakers, small electric motors, optical components, etc.), electric car motors, generators on the wind turbine. Regarding the progress of the implementation of the industrialization program for processing rare earth metal resources by PT TIMAH Tbk, MEDIABUMN.COM quoted Abdullah Umar as the Corporate Secretary of PT TIMAH Tbk that it was still looking for partners in processing rare earth elements resources. “Regarding the development of this rare earth elements, we are still at the stage of looking for partners. Because it is related to the use of advanced technology” Umar explained in a Public Expose Live, Friday (28/8/2020). In response to this, PT Trinitan Metals and Minerals (TMM) Tbk with no. letter 108 / TMM / IX / 2020 dated September 14, 2020 has sent a letter regarding his readiness to become a partner to the president director of PT TIMAH Tbk. PT TMM Tbk is a company that has experience in the use of hydrometallurgical process technology on a commercial scale. Currently, PT TMM Tbk is developing a STAL process as an alternative to HPAL for laterite nickel processing, and is also developing a mineral processing process for rare earth elements with a process technology similar to that of STAL. In developing this process technology, PT TMM Tbk collaborates with the Indonesian nuclear profession association (APRONUKI) considering that the processing of rare earth element-carrying minerals produces a by product in the form of TENORM (Technologically Enhanced Naturally Occurring Radioactive Material). Development of processing technology for rare earth elements bearing minerals must be developed domestically, given the Chinese government policy that prohibits licensing of rare earth element processing technology outside of China. The only rare earth elements bearing mineral processing company outside China that currently operates is Lynas in Malaysia with raw materials from Australian Mountweld. Even then, using conventional Chinese technology. China is currently developing process technology for the production of rare earths towards environmentally friendly technology. Several countries outside China are also currently developing process technology that is environmentally friendly and has a higher recovery of rare earths at the pilot plant stage. In Indonesia, the technology is also developed in pilot plant stage and at present is in the effort to optimize techno-economic. Therefore, at this time there is no reason for companies in Indonesia that will produce rare earths not to use domestic technology in processing rare earth elements.

FGD PUU BK-DPR RI with APRONUKI:

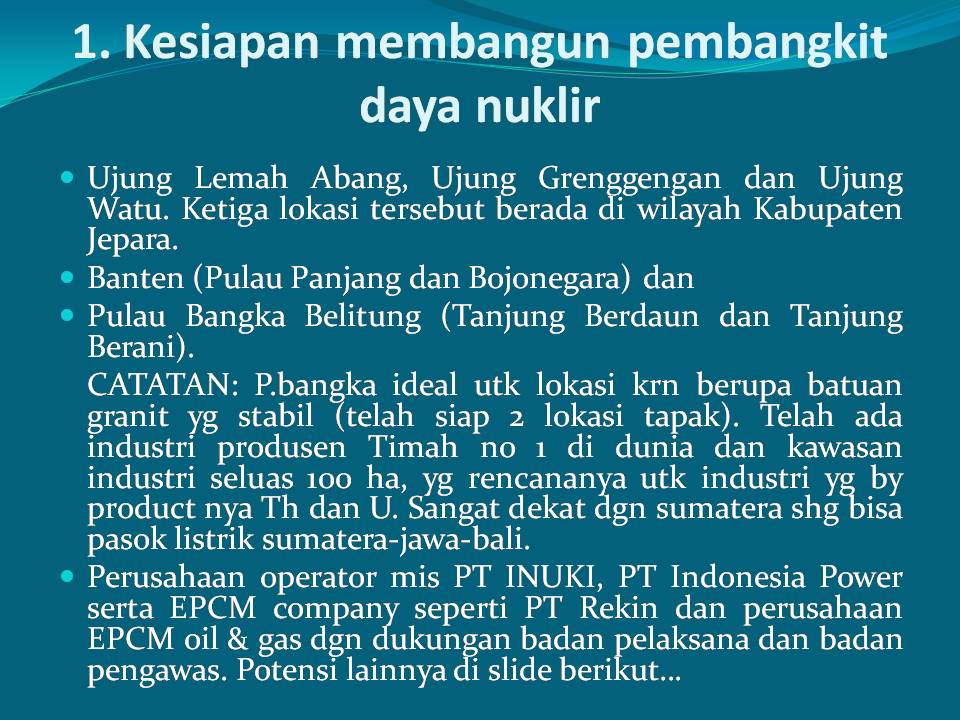

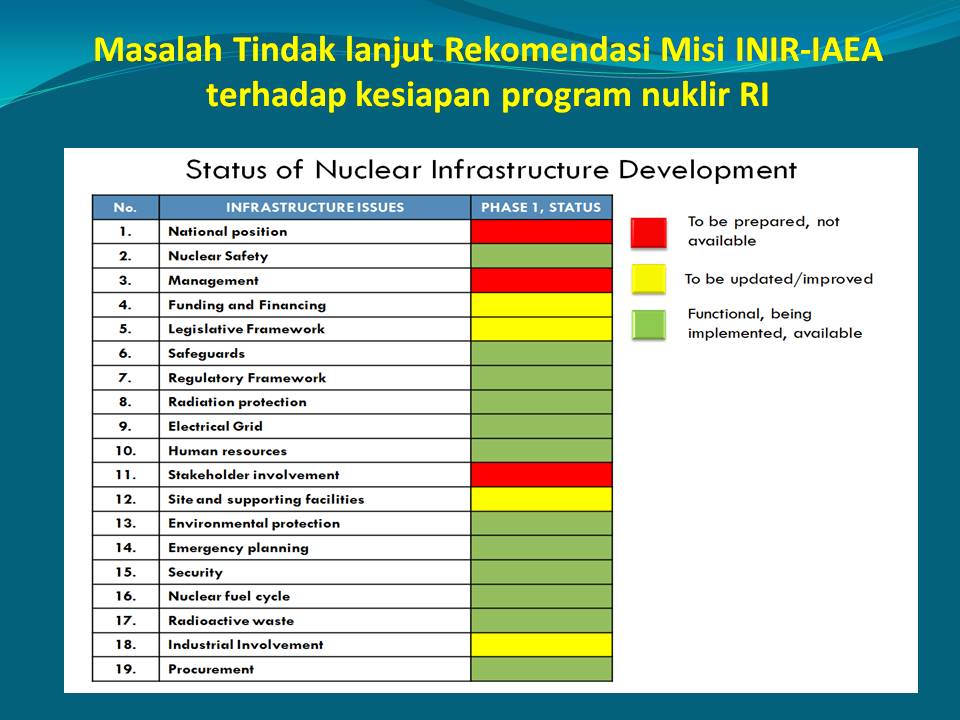

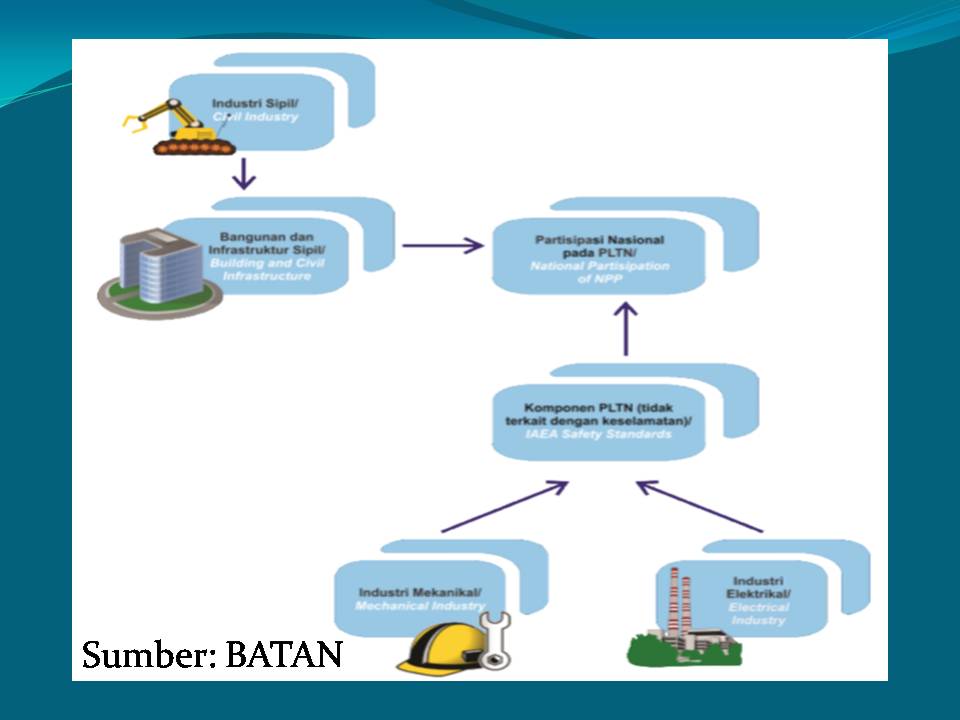

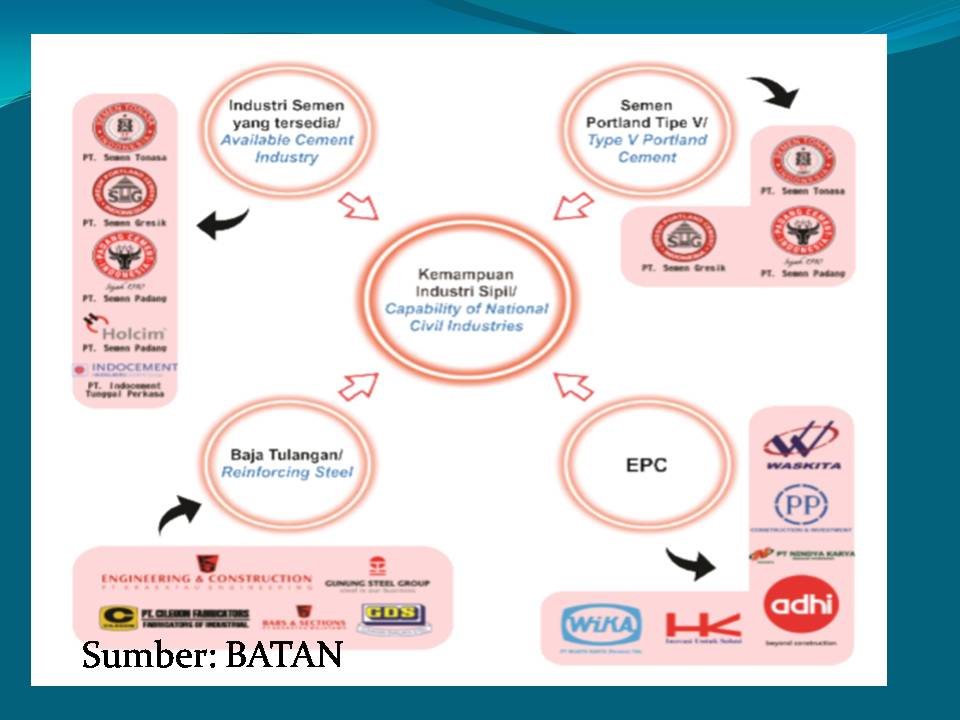

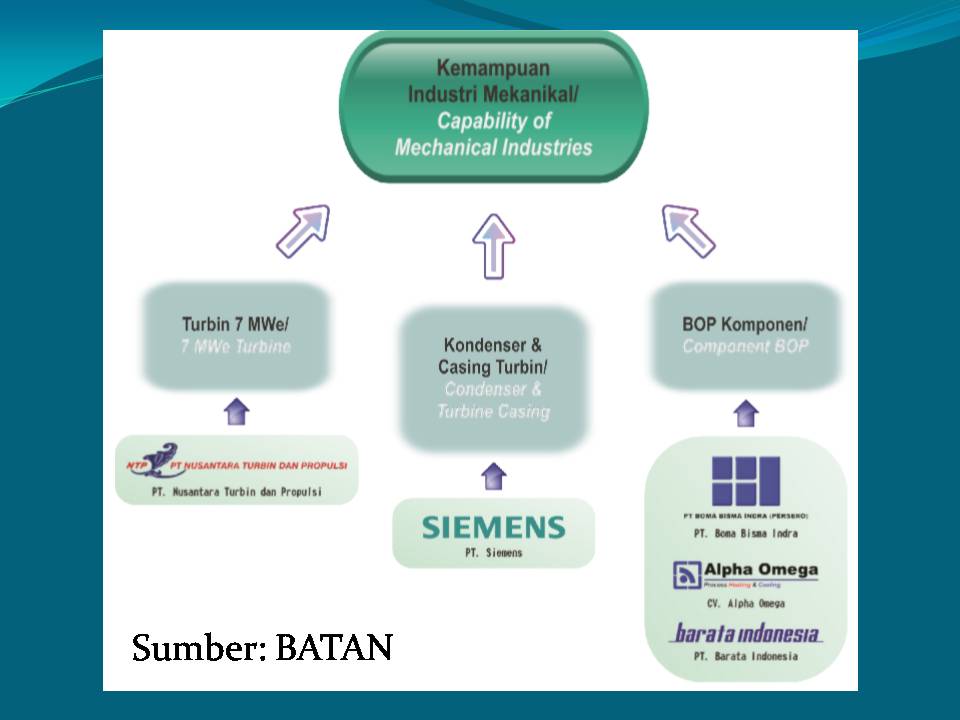

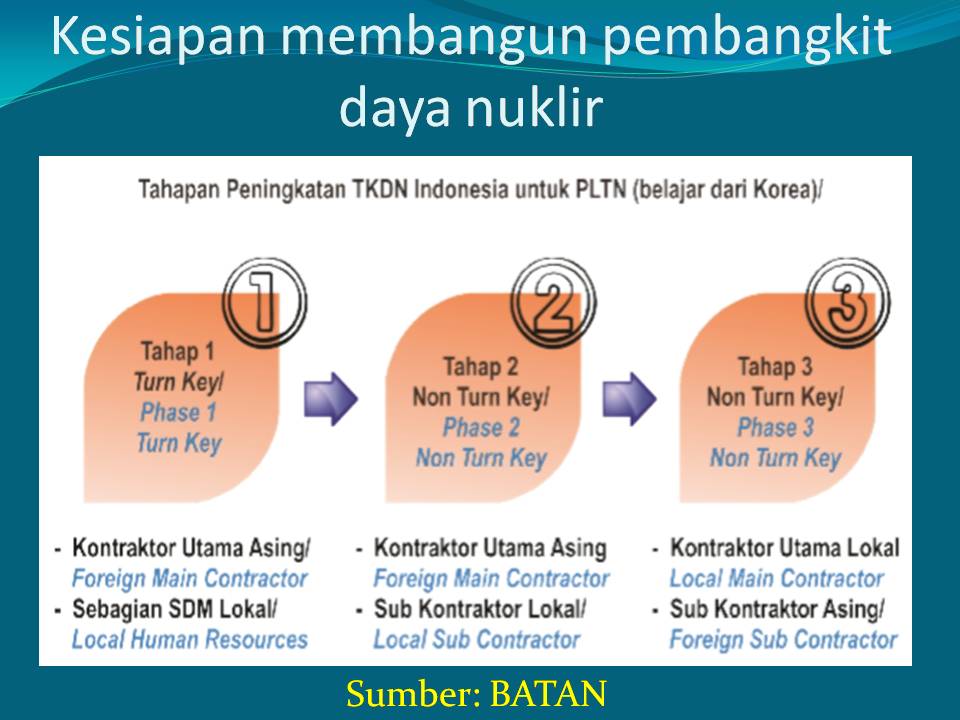

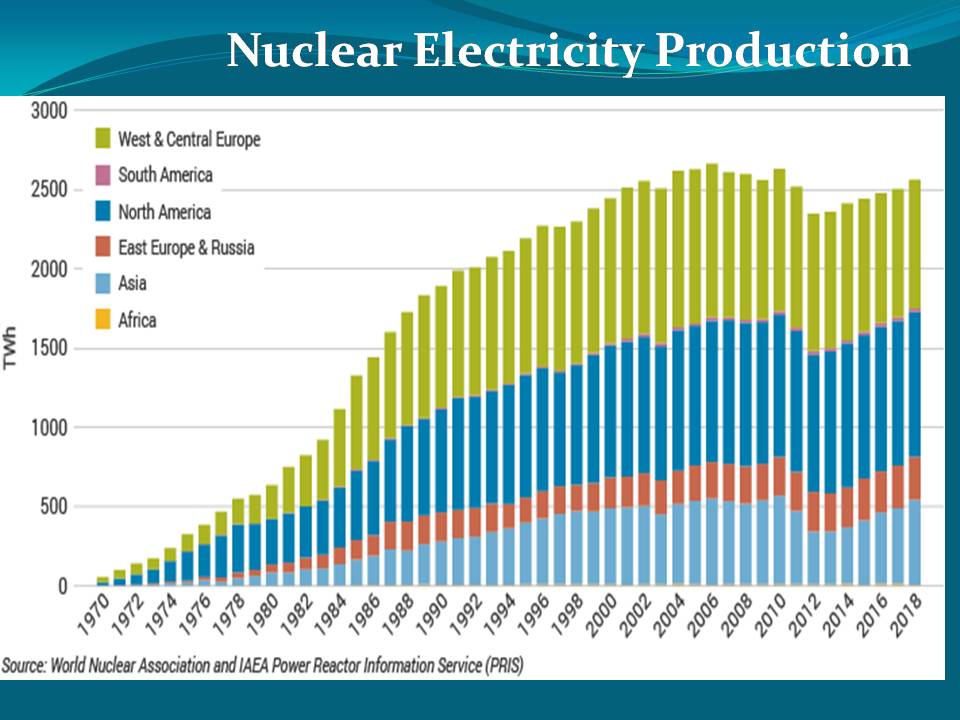

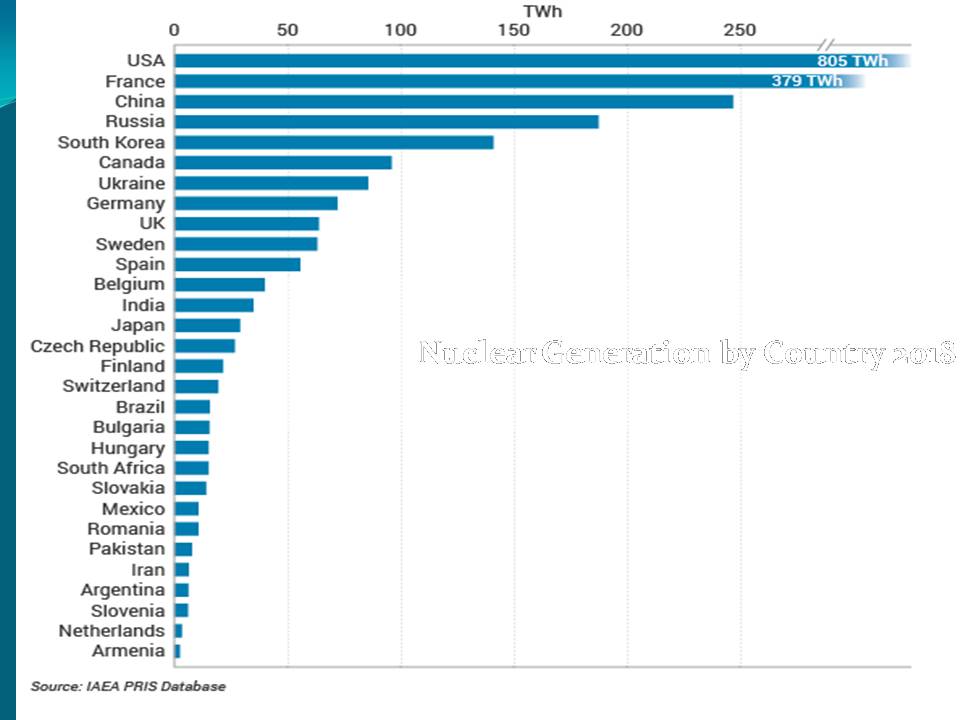

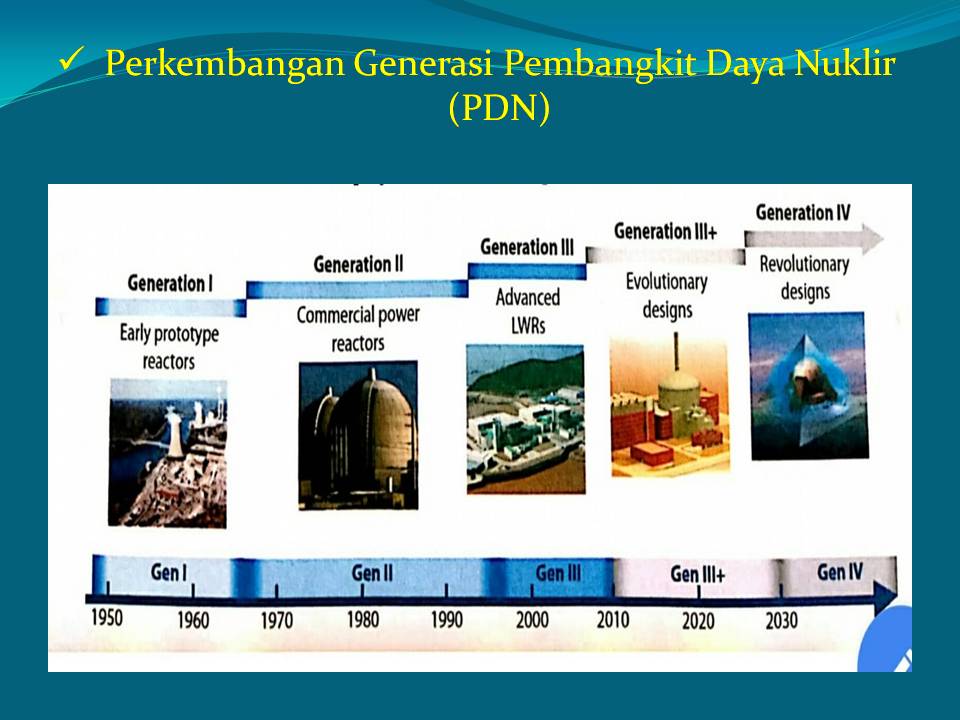

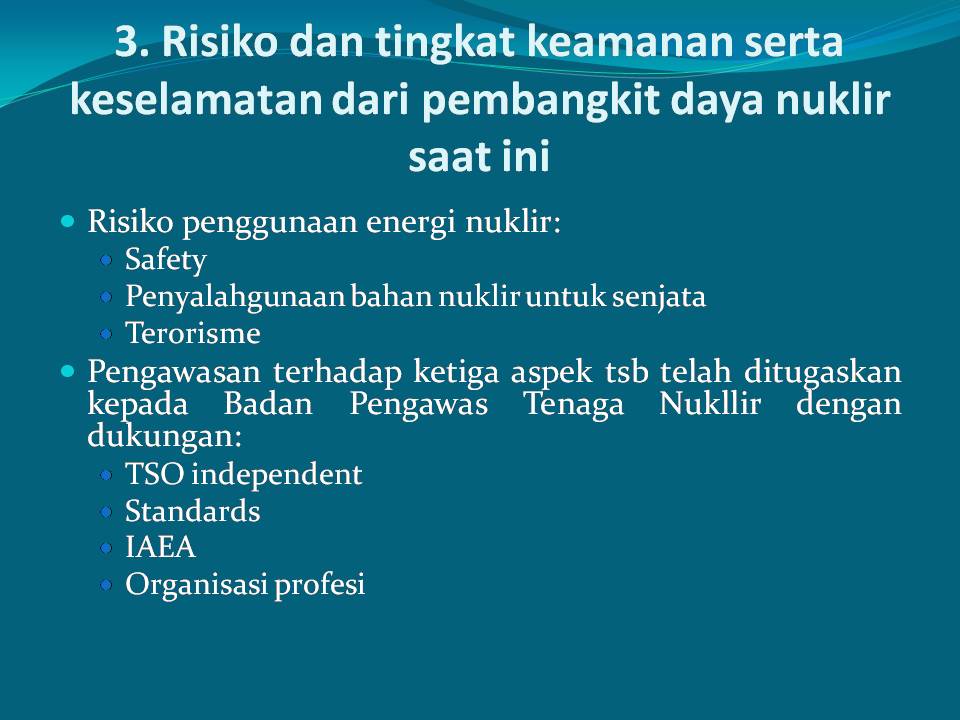

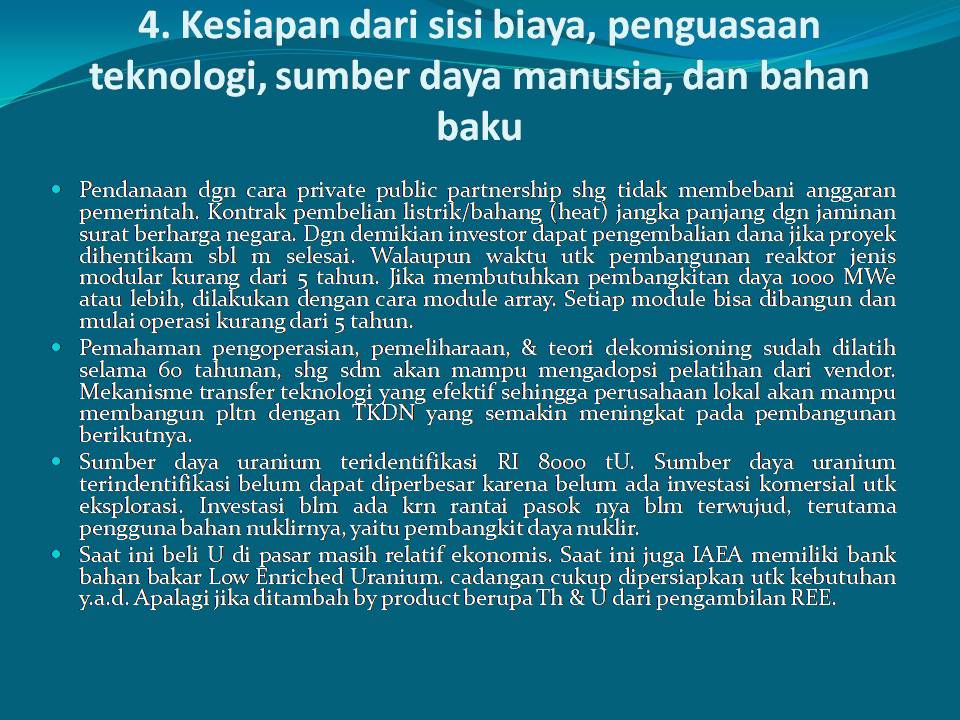

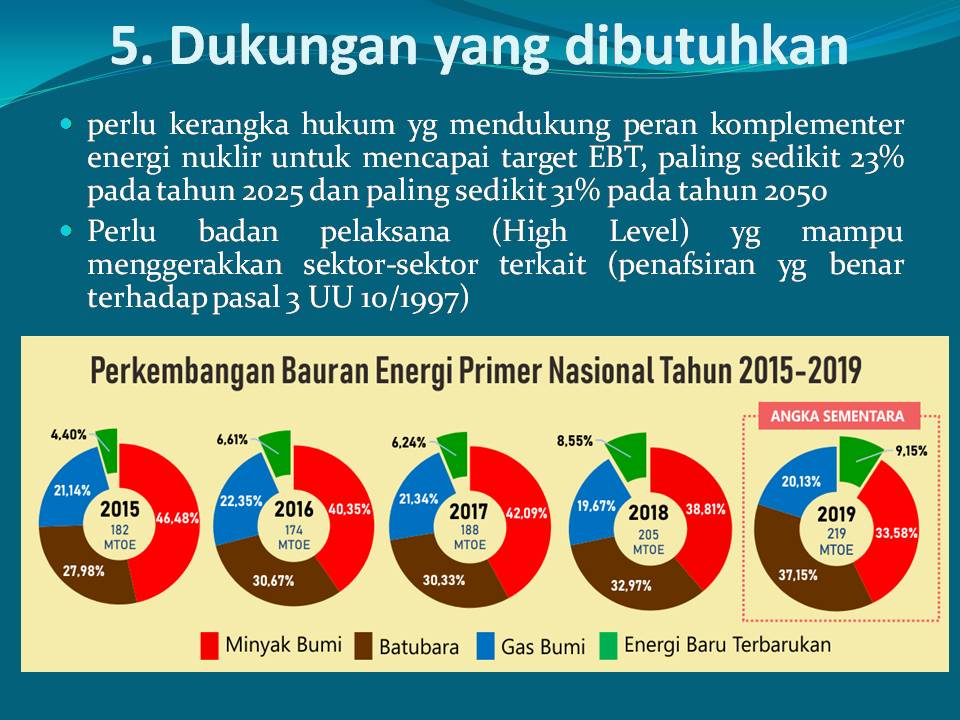

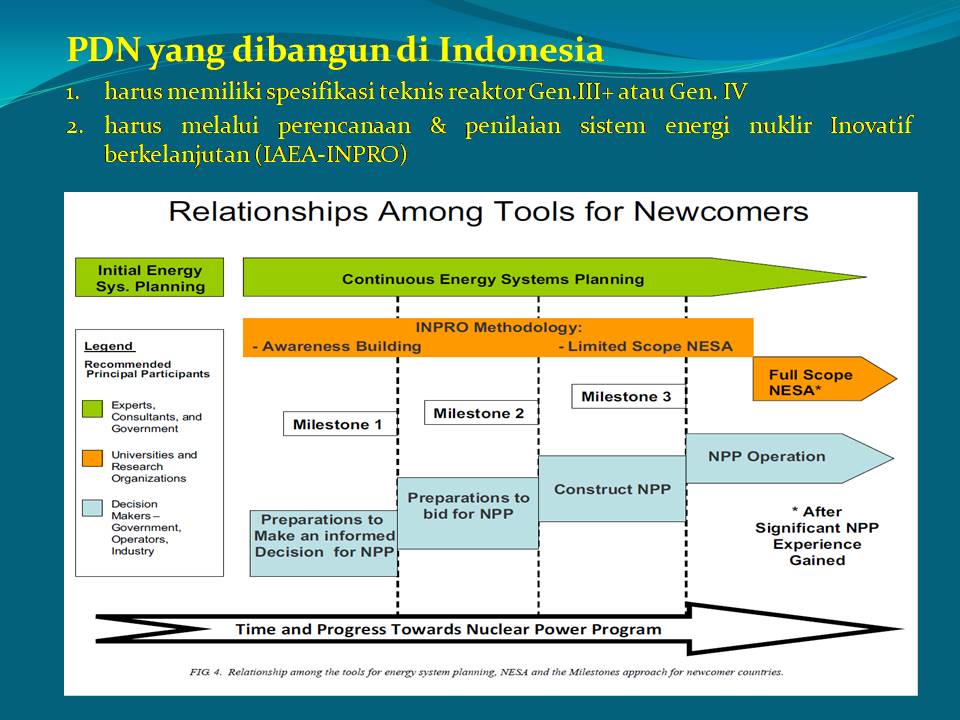

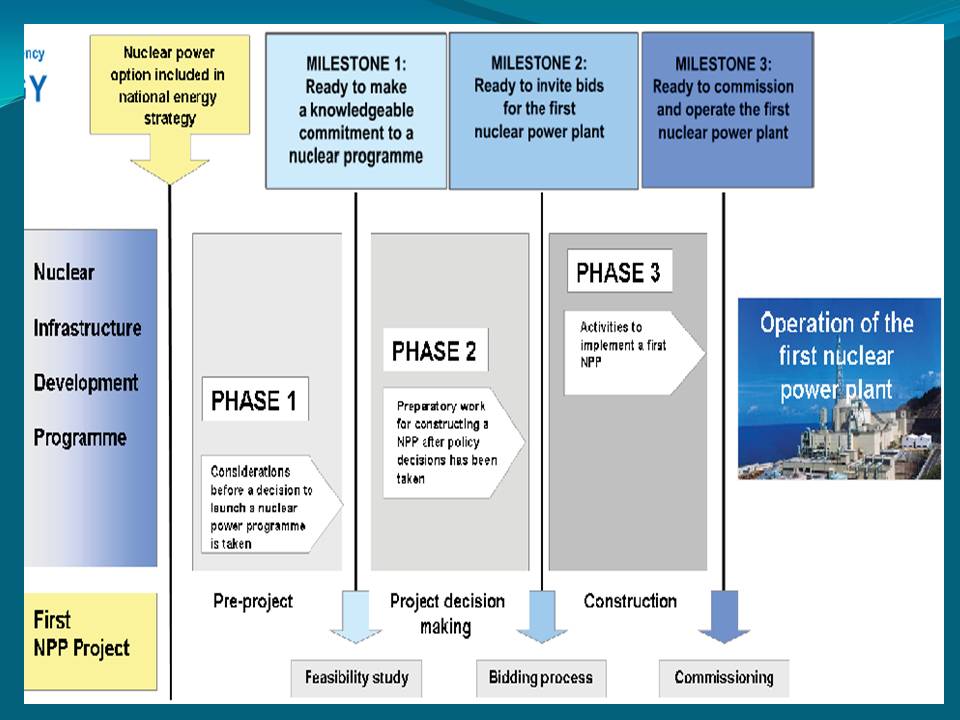

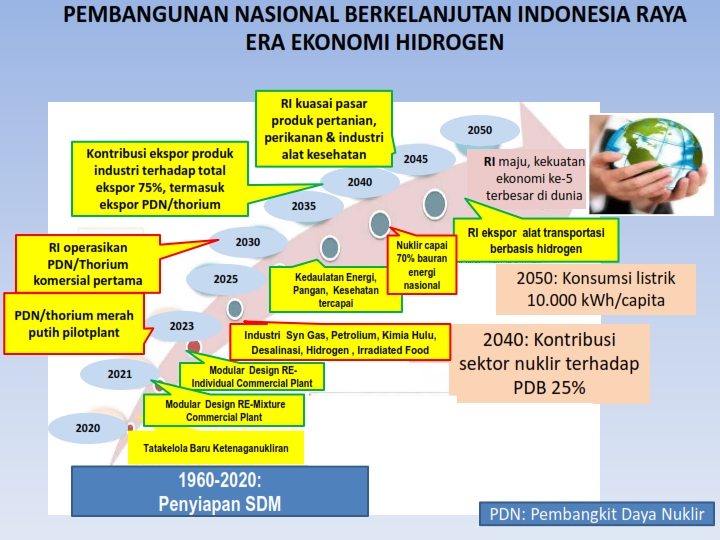

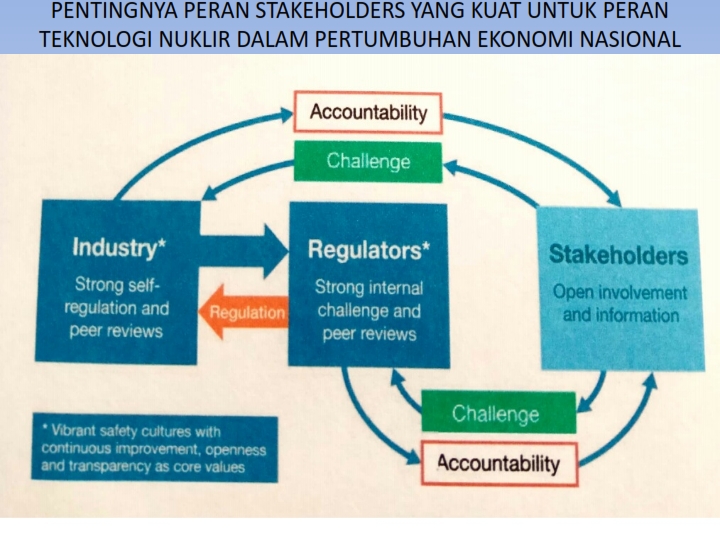

On the basis of a letter from the Secretariat General and the Parliament Expertise Body no: BK / 08019 / SETJEN AND BK DPR RI / PU / 7/2020, a Focus Group Discussion (FGD) was held in the framework of drafting an academic paper and draft law on New Energy and Renewable (EBT). The discussion related to this is the second stage of the first discussion on May 22, 2019 (letter no: BK / 077686 / SETJEN DAN BK DPR RI / PU / 05/2019). In the 2nd Term Of Reference discussion, it was stated that if we see the development of the utilization of new and renewable energy which is less than optimal, the option of realizing nuclear power plants should be put forward and not only as a last choice, as in Government Regulation (PP) No. 79 of 2014 concerning National Energy Policy. The next problem that needs to be answered when this option is put forward includes, are we ready to build a nuclear power plant? How is the development of the use of nuclear energy for electricity generation today globally? What about the risks and the level of security and safety of nuclear power plants today? How is the readiness in terms of costs, mastery of technology, human resources, and raw materials? What kind of support is needed to make this option possible? What forms of regulation need to be prepared in the regulation? What about the current level of public acceptance of nuclear power plants? APRONUKI answers these questions in the form of a presentation delivered by the Chairperson of APRONUKI as shown in the following slide. The PUU BK-DPR RI FGD with APRONUKI was attended by 19 participants.

Our hope:

“Strengthening economic resilience for growth while still holding the commitment of the Indonesian government in UNFCCC COP 21 2015 to reduce Greenhouse gases (GHG) emissions by at least 29% in 2030”.

Natural resources are God’s gift to be used responsibly so that nature will continue for the next generation of nations. Increasing the added value of natural resources requires energy.

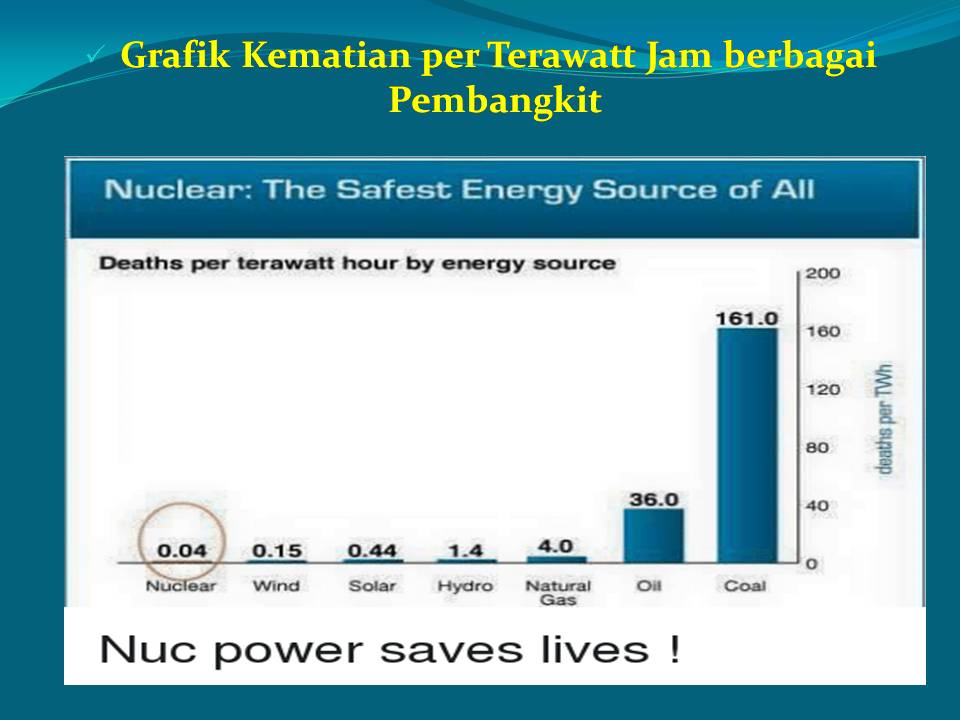

Errors in the selection of energy will result in damage to nature, including human health. Therefore, the Indonesian government in UNFCCC COP 21 2015 is committed to reduce GHG emissions by a minimum of 29% in 2030.

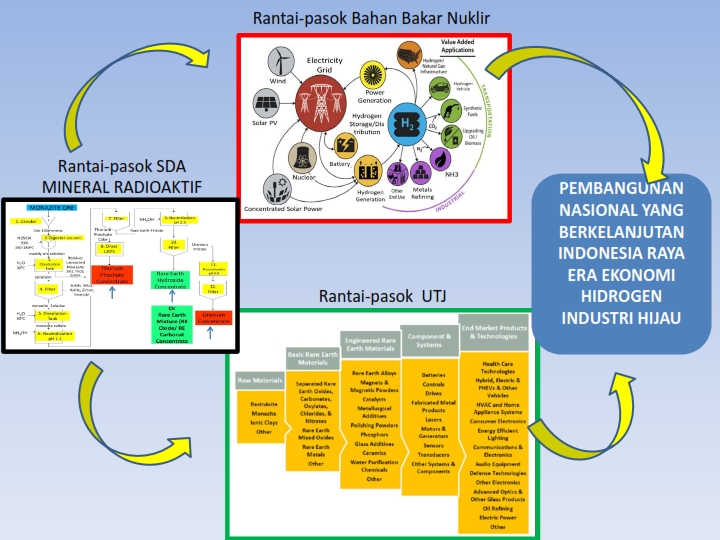

The use of fossil fuels as an energy source to increase the added value of natural resources contributes greatly to GHG emissions. GHG emissions also come from transportation which currently uses fossil fuels. The solution to this problem is an effort to prioritize the use of new and renewable energy, such as nuclear, water, wind, sunlight, geothermal and biomass, in synergy to produce energy in the form of heat and electricity.

Electric generators for wind turbines in wind power plants use rare earth elements magnets that are powerful and small in size. In general, rare earths from radioactive minerals containing nuclear fuels such as Uranium and Thorium.

Likewise, electric motors for electric vehicles also use rare earth elements.

GHG emission reduction must also be done in transportation. At present the use of fuel cell electric vehicles (FCEV) has become a trend. In the market, FCEV is already available such as Toyota Mirai, Honda Clarity, Hyundai Nexo. etc. FCEV’s fuel is hydrogen, and the exhaust gas is only water vapor.

Hydrogen is obtained from the water splitting process, especially from the abundant sea water. Fossil fuels can be also converted to hydrogen. The process of making hydrogen, both from water splitting and conversion from fossil fuels, requires heat. Considering the Indonesian government’s commitment to reduce GHG emissions, the generation of such heat should not lead to GHG emissions. Nuclear power plant generate heat and electricity without emitting GHG.

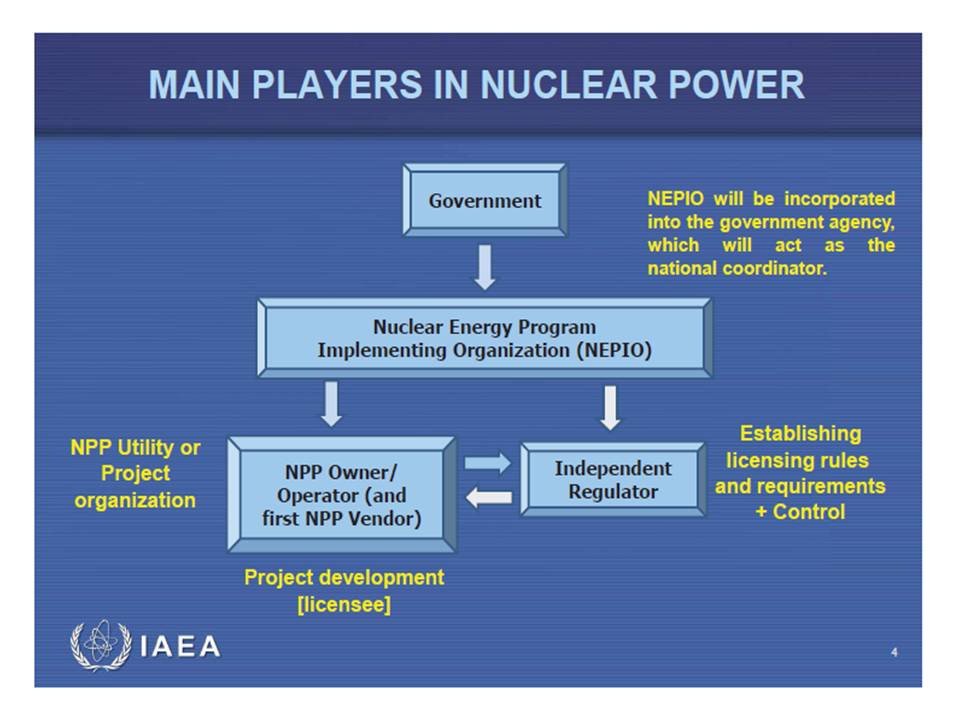

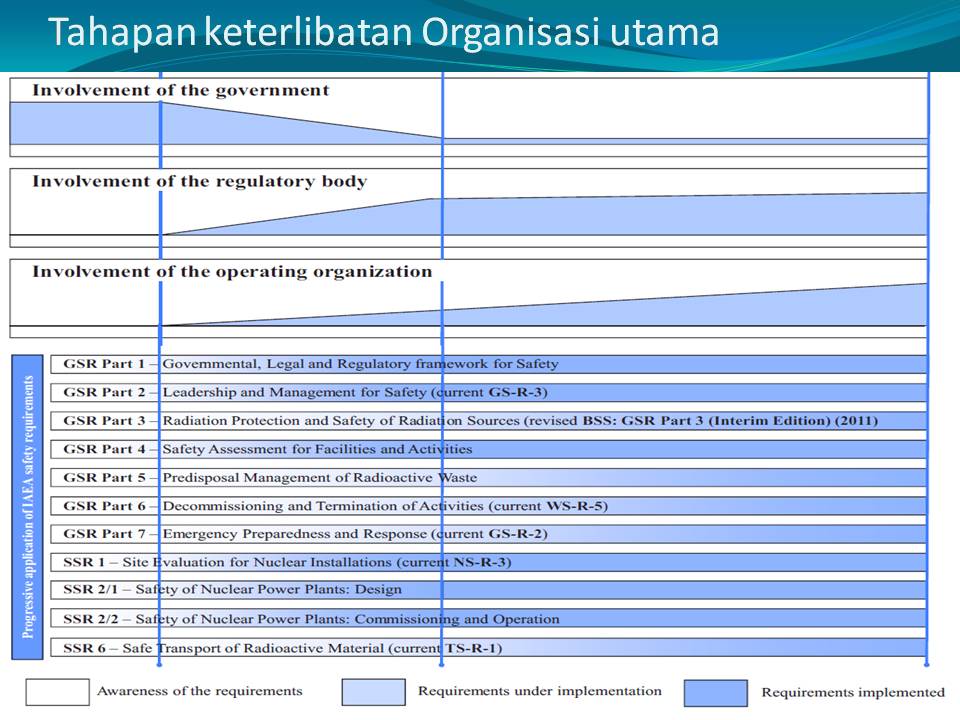

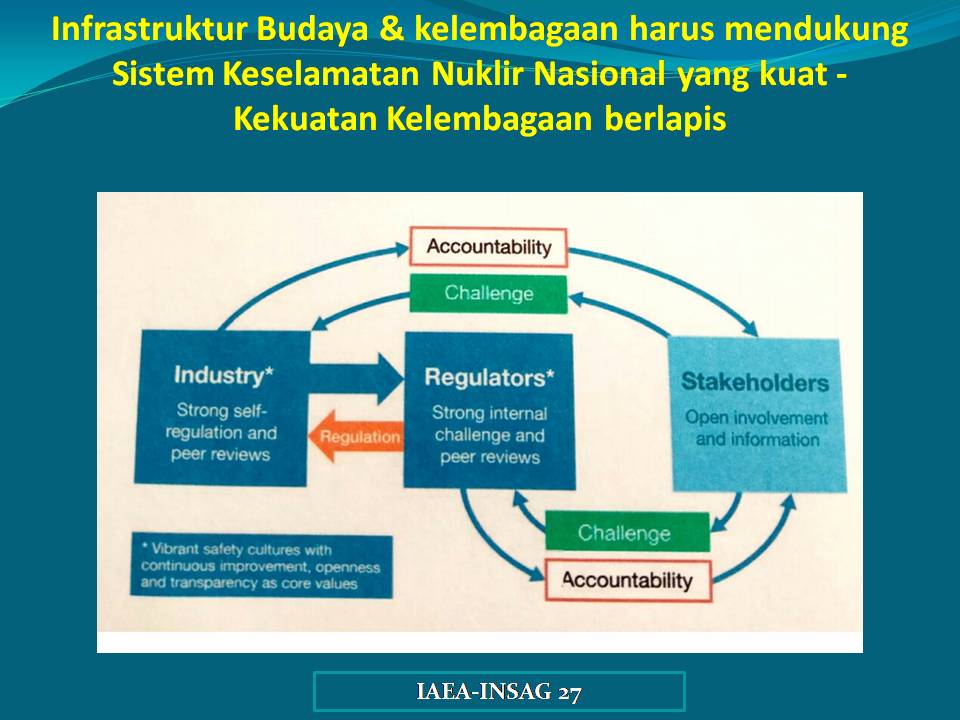

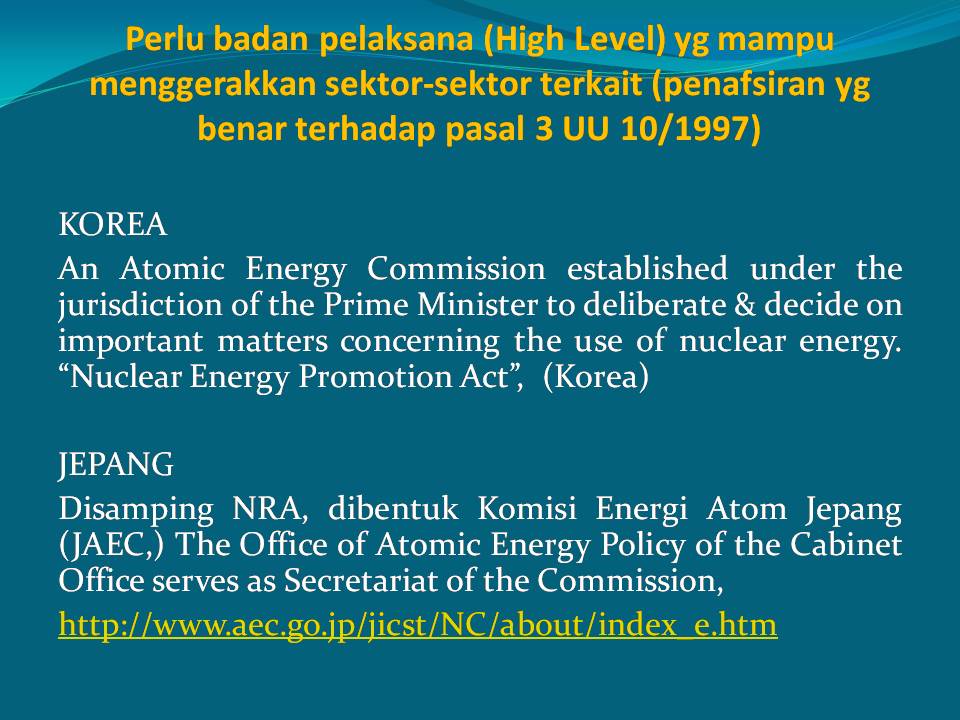

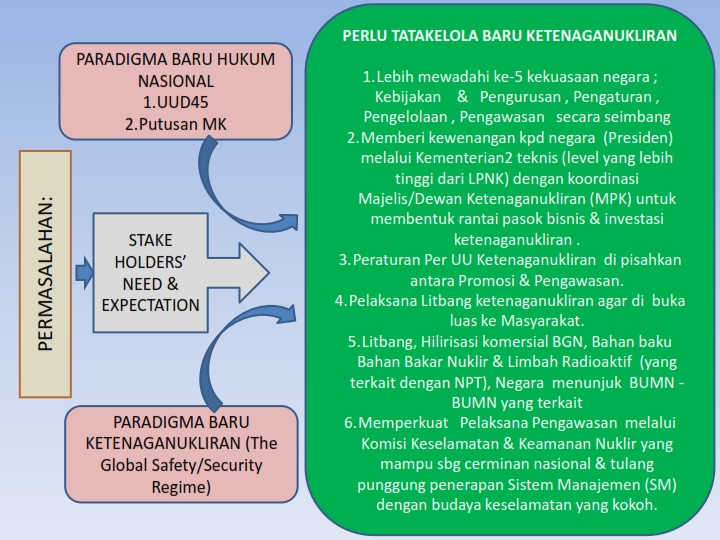

Based on the new paradigm of national law and the global safety/security, it is required a new nuclear governance which accommodates all 5 state powers: policies (beleid) & administrative actions (bestuursdaad), regulatory act (regelendaad), management (beheersdaad), supervision (toezichthoudensdaad) in a balanced way.

A Proposed New Nuclear Governance:

APRONUKI has proposed 17 focus review areas for Molten Salt Reactor (MSR) and High Temperature Gas Cooled Reactor (HTGR) to BAPETEN (The Nuclear Energy Regulatory Agency of Indonesia):

1. Considering the passive safety features promised / owned by MSR and HTGR which are based on natural phenomena, not engineered safety features, it is deemed necessary to review regulations related to power (commercial) reactors.

2. Learn from the Canadian Nuclear Regulator CNSC which has adopted the IAEA Safety Standard Series SSR-2/1 (Rev 1) “Safety of Nuclear Power Plants: Design-specific Safety Requirements” to compile REGDOC-2.5.2. Based on the REGDOC, 19 focus areas of the review that were used by CNSC in the Gen-IV reactor pre-licensing process included IMSR (Integrated Molten Salt Reactor) from Terrestrial Energy.

3. For Gen-IV, in REGDOC-2.5.2 there is chapter 11 on “Alternative Approach”.

4. APRONUKI adopted SSR-2/1 rev 1 to compile 17 focus review areas that have been proposed to BAPETEN.

5. Initial discussion on 17 focus review areas was conducted in a focus group discussion (FGD) with BAPETEN. In the focus area (focus area 7 on safety analysis) it is proposed to apply the risk-based review principle to determine the relevance of each focus area for reviewed nuclear power plants. In the FGD, BAPETEN stated that licensing of new types of reactors (such as MSR and HTGR) could be carried out with licensing mechanisms on the basis of experiments. For this reason, the reactor vendor can work with the Implementing Agency (BATAN) to build an experimental reactor.

6. The 17 focus review areas which are proposed by APRONUKI still need to be discussed in more detail with BAPETEN, especially for the preparation of guidelines that will be taken into consideration in improving regulations relating to existing new Nuclear Power Plants (especially BAPETEN regulations on Safety Provisions of Power Reactor Designs).

Health

Nuclear technique for medical diagnostic equipments such as renograph, Gamma Camera, PET-CT etc., and therapetic equipments such as gamma knife, linac, gamma irradiator using Co-60… READ MORE

Industry

Nucleonic control system, NDT, production of isotopes for health, Electron Beam or gamma radiation for cross linking, degradation and sterilization processes,electron beam for flue gas treatment (Reduksi NO2 dan SOx), thorium, zirconium & rare earth elements extraction and purification and its aplications: … READ MORE

Regulation

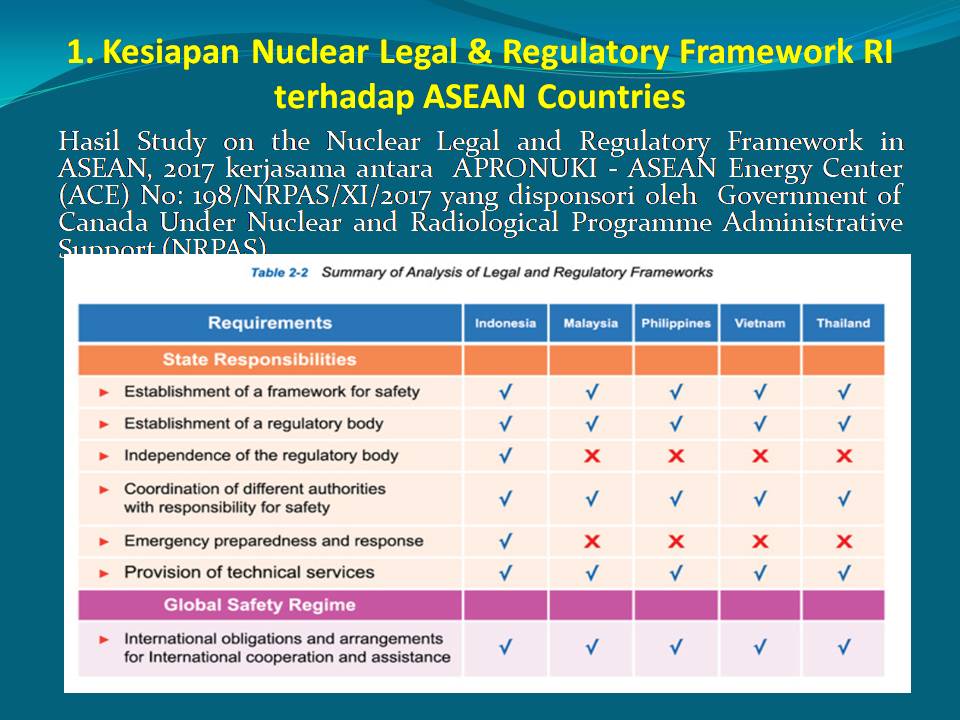

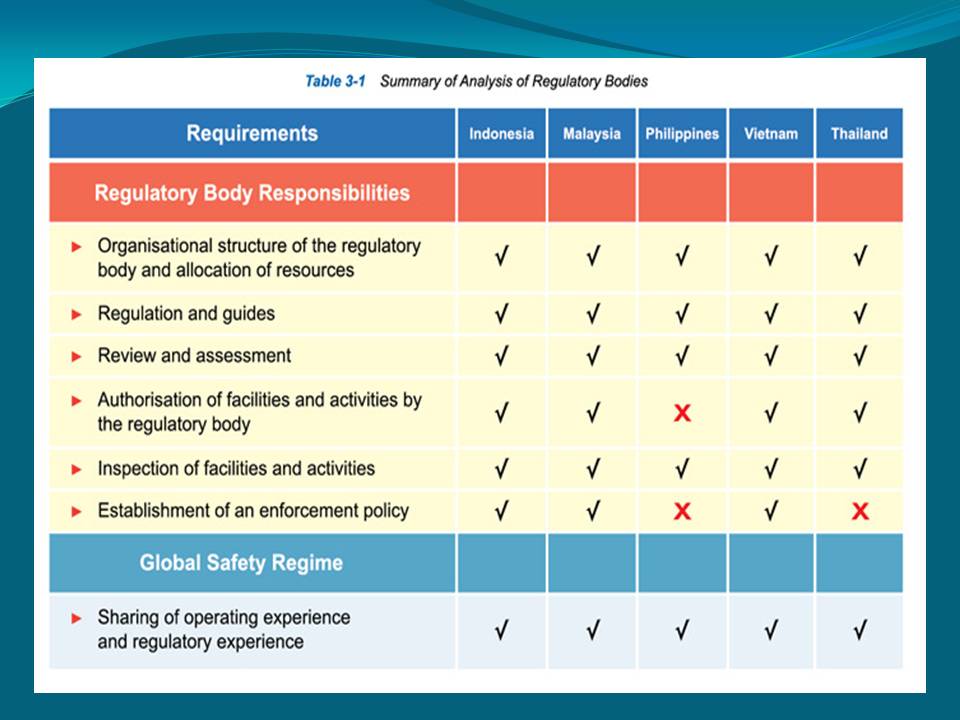

STUDY ON THE NUCLEAR LEGAL AND REGULATORY FRAMEWORK IN ASEAN… READ MORE

Environmental Issues

All materials in air, water, earth, plants, and also in the body of humans and animals content radioactive material which is called Naturally Occurring Radioactive Material (NORM). Concentrated NORM which is produced through ore processing, coal burning, etc, is called Technologically Enhanced Naturally Occurring Radioactive Material (TENORM)… READ MORE

Energy

Melting free nuclear reactor: High Temperature Gas Cooled Reactor, Molten Salt Reactor

Molten Salt Reactor

Molten Salt Reactor (MSR) which use thorium as its main fuel and Uranium as iniator for breeding the thorium. Operating pressure around atmospheric pressure, fuel and coolant freezes into solids at temperatures below 400 degrees Celsius are the main safety features of … READ MORE

High Temperature Gas Cooled Reactor (HTGR)

High Temperature Gas Cooled Reactor (HTGR), which is called as Catastrophe free nuclear reactor with a large local content potential due to the majority of the reactor core structure consists of graphite and concrete. HTGR produces heat (temperature around 900 degrees Celsius) and electricity. HTGR in Hamm Uentrop Germany is the first commercial plant in the world… READ MORE

Technology Transfer

HOW CHINESE GOVERNMENT USE A GREAT DOMESTIC MARKET for the needs of technology transfer and to achieve the goal of developing national technological capabilities (example of fast railroad technology): … READ MORE